Understanding the Role and Selection of Oil Seals in Modern Machinery #

Oil seals are indispensable components in a wide range of mechanical systems. Their primary function is to seal around rotating shafts, ensuring that lubricants remain contained within axles, engines, or other assemblies. This article explores the essential functions, styles, and designs of oil seals, and provides guidance on choosing a suitable manufacturer for your needs.

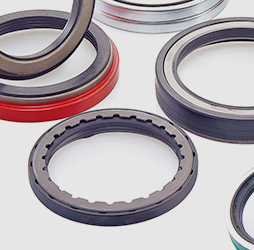

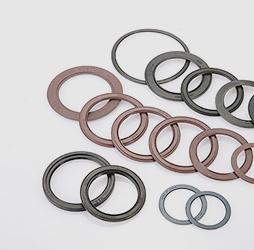

Oil Seal

Oil Seal

Special Seal

Special Seal

Oil Seal

Oil Seal

Oil Bath Seals

Oil Bath Seals

Oil Seal

Oil Seal

Oil Seal

Oil Seal

Oil Seal

Oil Seal

Oil Seal

Oil Seal

Oil Seal

Oil Seal

Oil Seal

Oil Seal

Oil Seal

Oil Seal

Oil Seal

Oil Seal

Essential Functions of Oil Seals #

Oil seals serve several critical purposes in machinery:

- Retaining Lubricants or Liquids: They prevent the escape of lubricants, ensuring smooth and efficient operation.

- Excluding Contaminants: Oil seals block dust, dirt, and moisture from entering, protecting internal components.

- Separating Fluids: They keep different fluids apart, preventing cross-contamination that could affect performance.

- Confining Pressure: Oil seals help maintain internal pressure, essential for hydraulic and other pressurized systems.

These functions make oil seals vital in applications ranging from pumps and automotive systems to industrial cylinders and more.

Common Styles of Oil Seals #

Oil seals are available in various styles to accommodate different operational requirements:

- TC: Single-lip, rubber-covered outer diameter (OD)

- SC: Double-lip, rubber-covered OD

- TA: Single-lip, bare steel OD

- SA: Single-lip, highly polished bright steel OD

- TB: Double-lip, bare steel OD

- SB: Double-lip, highly polished bright steel OD

- VC: Single-lip, coated OD

Manufacturers like LYO Oil Seal offer a range of OD width options, including ground, polished, coated, and painted ODs, with rubber to fill minor housing imperfections.

Oil Seal Designs #

The design of an oil seal is chosen based on the application’s pressure and sealing requirements:

- Single-lip Seals: Feature one lip contacting the shaft, suitable for low-pressure environments.

- Double-lip Seals: Incorporate two lips for enhanced sealing, ideal for higher-pressure applications.

- Triple-lip Seals: Provide three lips for maximum sealing performance, used in demanding, high-pressure conditions.

Selecting a Reliable Oil Seal Manufacturer #

Given the critical role of oil seals in industries such as oil and gas, aerospace, automotive, chemical, and power generation, choosing the right manufacturer is essential. Consider the following factors:

- Experience and Expertise: Look for a proven track record in oil seal production.

- Quality Assurance: Ensure adherence to strict quality standards for consistent, high-quality products.

- Customer Service: Responsive support and timely order fulfillment are important.

- Customization Capabilities: The ability to deliver custom-molded oil seals for specific applications adds value.

Lian Yu Oil Seal Enterprise: Expertise and Capabilities #

Established in 1978, Lian Yu Oil Seal Enterprise Co., Ltd. is recognized for its high-quality oil seals, serving diverse industries worldwide. With over four decades of experience, Lian Yu offers a comprehensive range of products, including bus oil seals, oil bath seals, industrial oil seals, special seals, rubber seals, and vehicle oil seals.

The company invests in advanced technology and employs experienced engineers to remain at the forefront of oil seal design and manufacturing. Custom-molded oil seals are available in a variety of materials, shapes, and sizes to meet unique requirements. For more information about custom solutions and services, contact Lian Yu Oil Seal.

Cross-Reference Table for Oil Seal Styles #

Below is a cross-reference of oil seal styles among major manufacturers:

| Style | LYO | Gaco | Pioneer Weston | Goetze | Kaco | NAK | National | Garlock | NOK | Paulstra | Simmerwerke | Simrit-Freudenberg | Chicago Rawhide | Stefa |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SC | SC | A | R21 | 827N | DG | SC | 35 | 92 | SC | IE | A | BA | - | CB |

| TC | TC | FA | R23 | 827S | DGS | TC | 32 | 94 | TC | IEL | ASL | BASL | - | CC |

| VC1 | VC1 | ABI | R4 | 822N | DF | VC1 | 48 | 71,91 | VC1 | EE | B | B1 | CRW1 | BB |

| SB | SB | - | R6 | 822S | DFS | SB | 47 | 76 | SB | EEL | BSL | B1SL | CRWA1 | BC |

| SA | SA | - | R1 | 824N | DFK | SA | 45 | 68 | SA | EEP | C | B2 | CRWH1 | DB |

| TA | TA | - | - | 824S | DFSK | TA | 41 | - | TA | - | CSL | B2SL | CRWHA1 | DC |

For further details on oil seal applications, cross-references, and technical support, visit the application page or explore the cross-reference/interchange table.