Comprehensive Guide to Oil Seal Applications and Product Types

Table of Contents

Understanding Oil Seal Selection and Applications #

Selecting the right oil seal for a specific application is crucial and depends on the operating conditions the seal will encounter. This guide provides detailed information on the types of seals offered by LYO and their intended uses, helping you make informed decisions for your sealing needs.

High Quality Product Groups #

Group A: Shaft Seals #

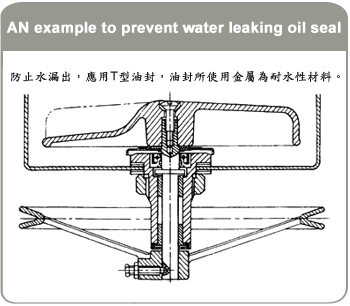

One of the most widely used designs, Group A shaft seals are press-fitted into the housing bore. The sealing is achieved through the sliding surface contact between the seal lip and the shaft. A close-coiled helical spring is incorporated to maintain effective sealing.

Group B: External Seals #

External seals are press-fitted onto a shaft, with the lip and housing bore providing sliding surface contact. These are used in specific scenarios where traditional shaft seals are difficult to install. Pitch-coiled springs are utilized in this design.

Product Range Overview #

Rubber to Metal Bonding #

- Bonding rubber to metal

- Bonded poppets

- Bonded valve seats

- Cushion seals

- Rubber rolls

- Scraper rings

- Custom-made bearing seals

Rubber Seals #

- O-rings

- V-rings

- U-cups

- Wiper rings

- Piston cups

- Custom-made seals

Molded Rubber #

- Special custom shapes

- Diaphragms

- Special boots

- Fabric reinforced seals

- Braided packings

- Static seals

Gaskets #

- Rubber

- Asbestos

- Vellumoid fiber

- Cork and cork-rubber

- Teflon

- Fiber

- Felt

- Sponge

Teflon Parts #

- Teflon coating (“Buckote Process”)

- V-rings

- O-rings

- Cups

- Backup washers

- Slipper seals

- Special shapes

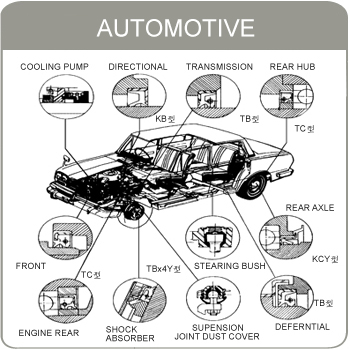

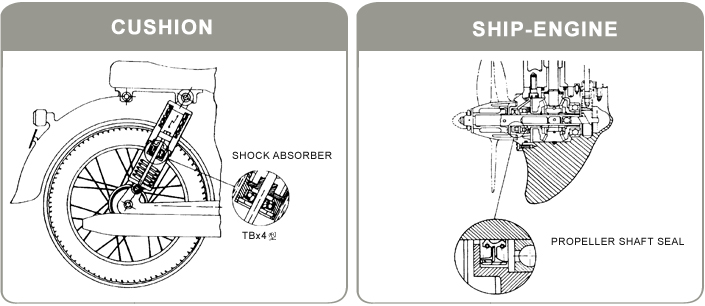

Key Application Areas #

Power System

Power System

Agriculture, Mining and Heavy Industry

Agriculture, Mining and Heavy Industry

Industrial Application

Industrial Application

Industrial Application 2

Industrial Application 2

Pulsator

Pulsator

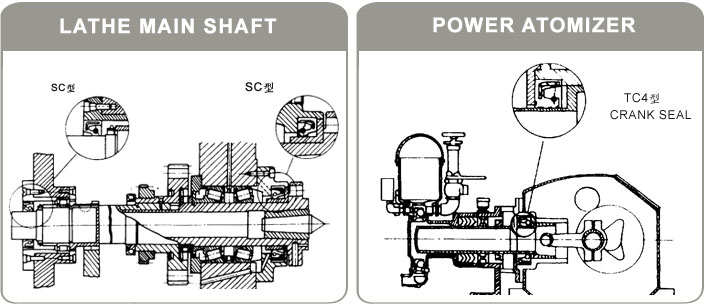

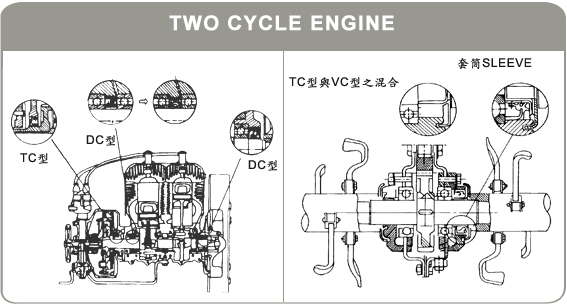

Machines and Tools (Engine Parts)

Machines and Tools (Engine Parts)

Custom Solutions #

Lian Yu Oil Seal Enterprise offers custom-made seals and components to meet unique requirements across various industries. Whether you need specialized shapes, reinforced materials, or tailored sealing solutions, our expertise ensures reliable performance in demanding environments.

There are no articles to list here yet.